感觉我最近只做自平衡机器人,但我又做了一次。 。 。 (^_^;)

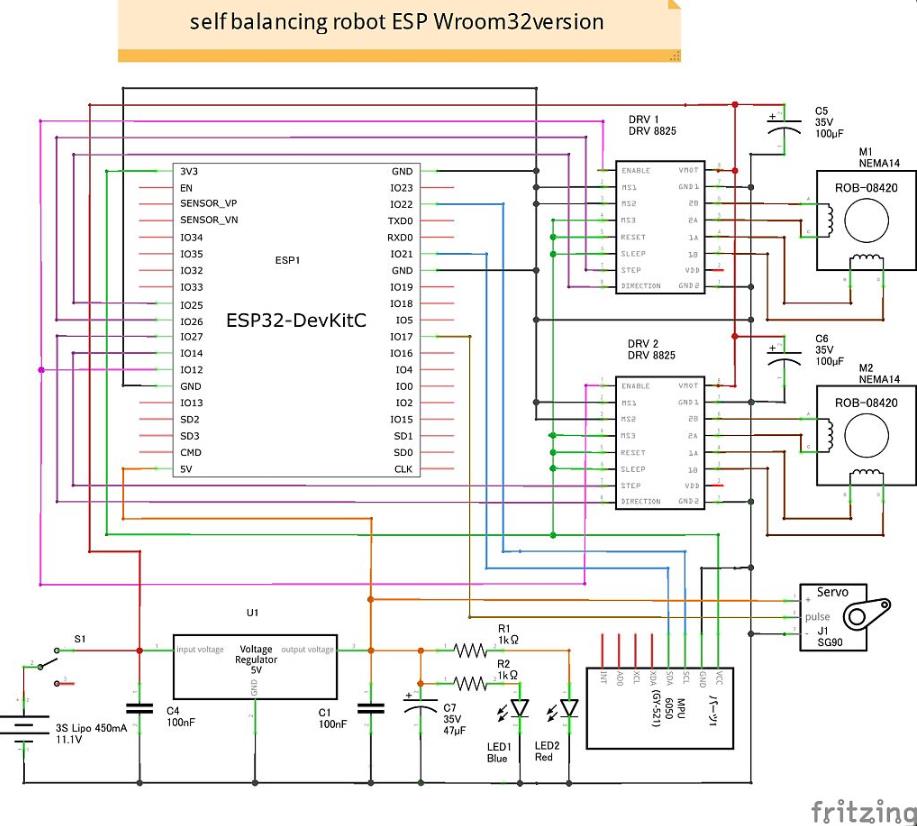

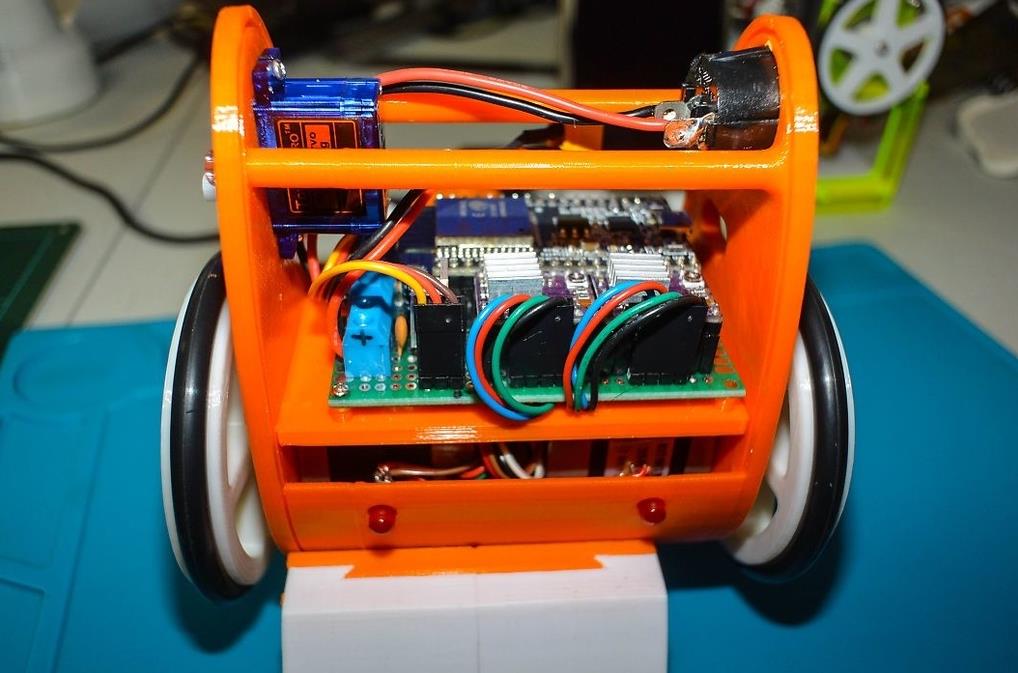

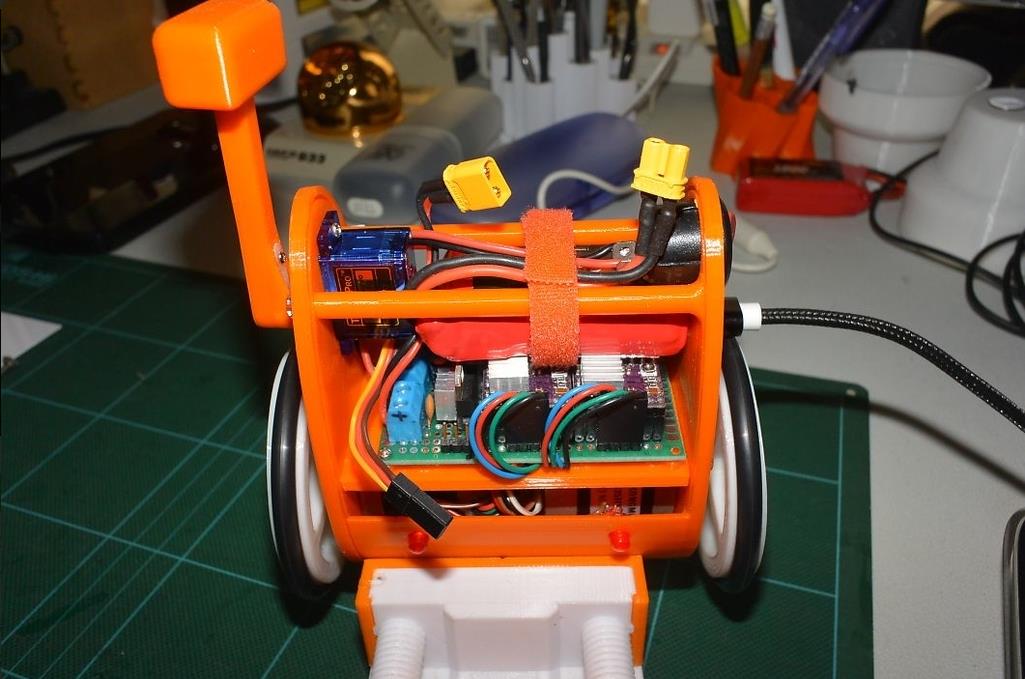

作为之前的改进,对车架进行了审查,增加了伺服系统,并将步进电机改为通用的 NEMA 14。

这款自平衡机器人基于 BROBOT EVO 打造,由 jjrobots 开源,在 B-Robot 论坛上架,但目前链接已死。

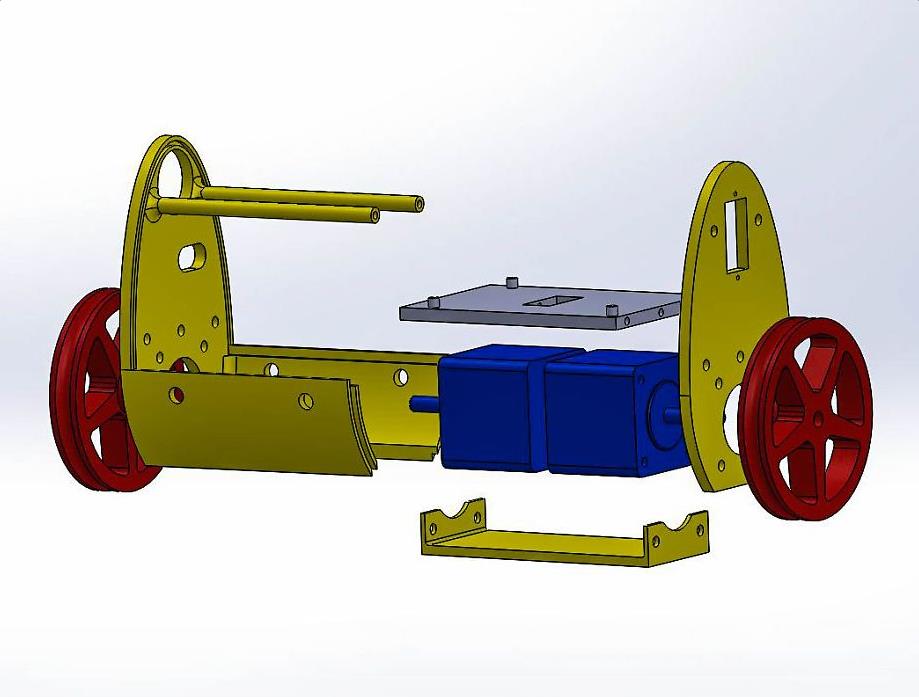

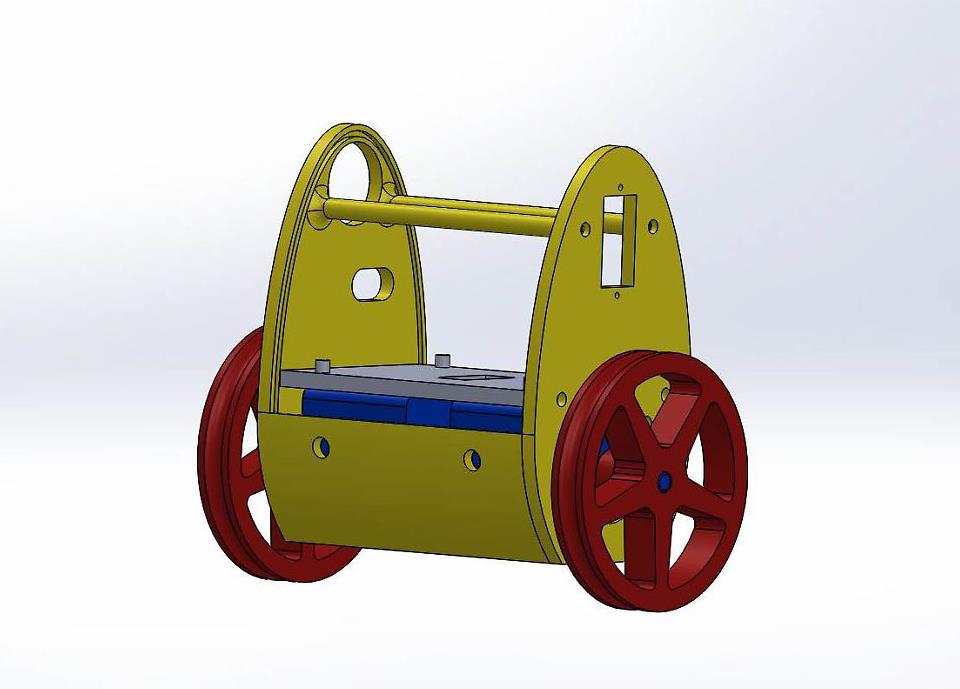

用 3D 打印机制作的框架

框架采用PLA灯丝,由于伺服安装和步进电机规格变化,与之前略有不同,但尺寸几乎相同。 这是开发图和装配的图像。

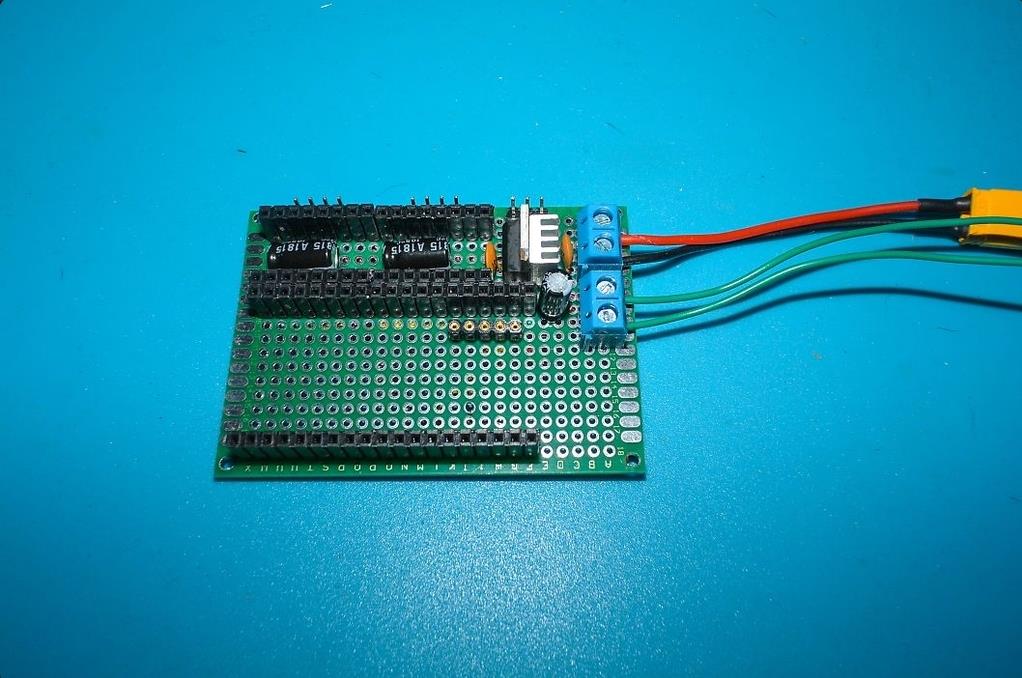

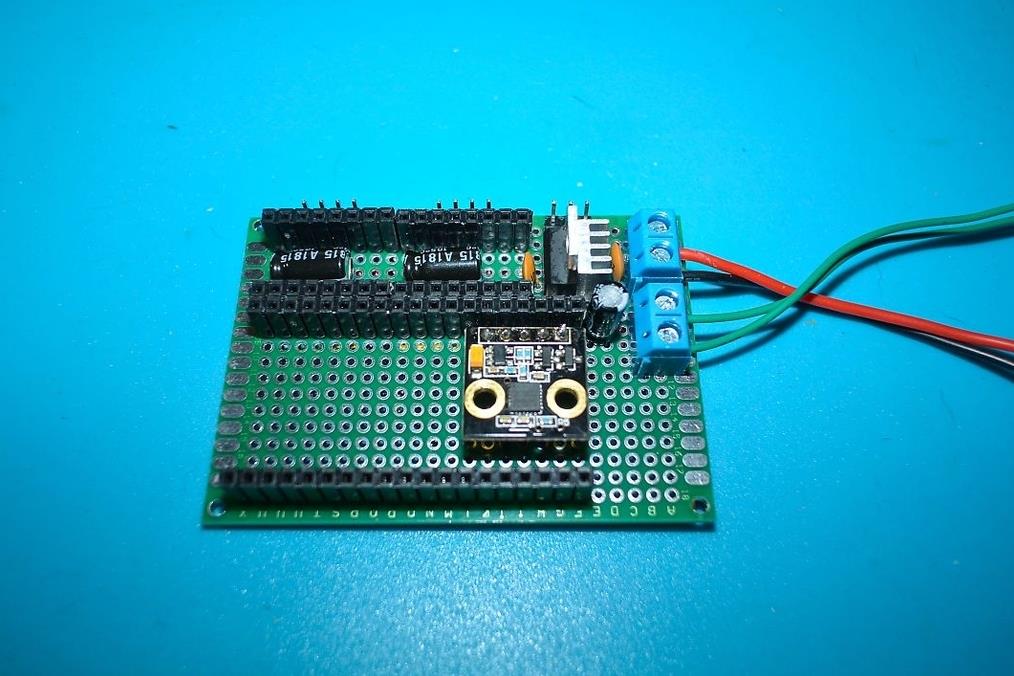

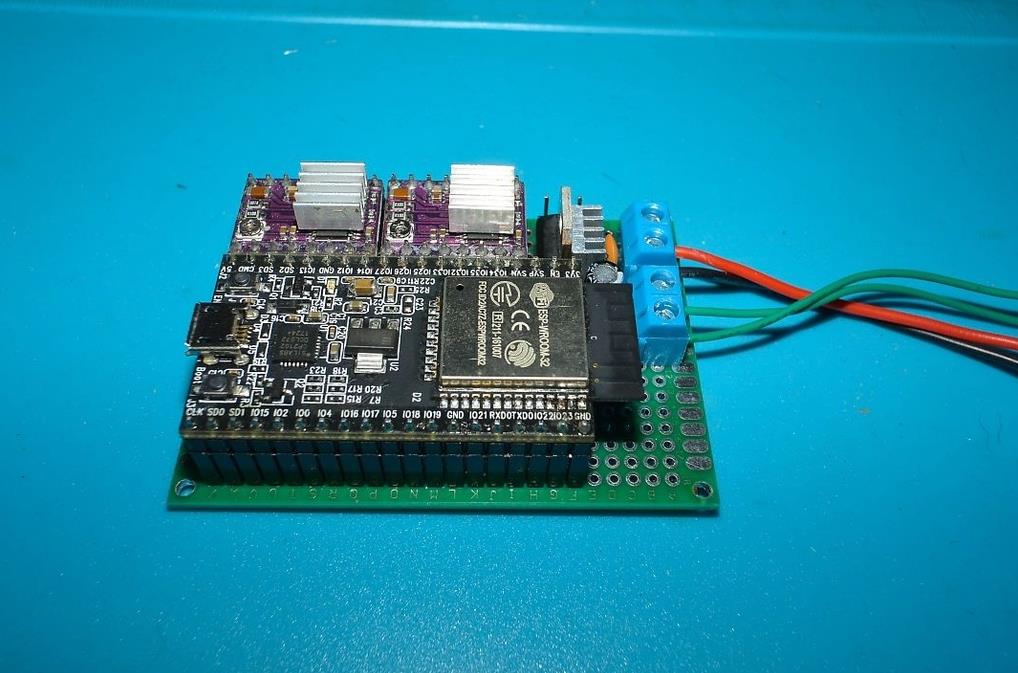

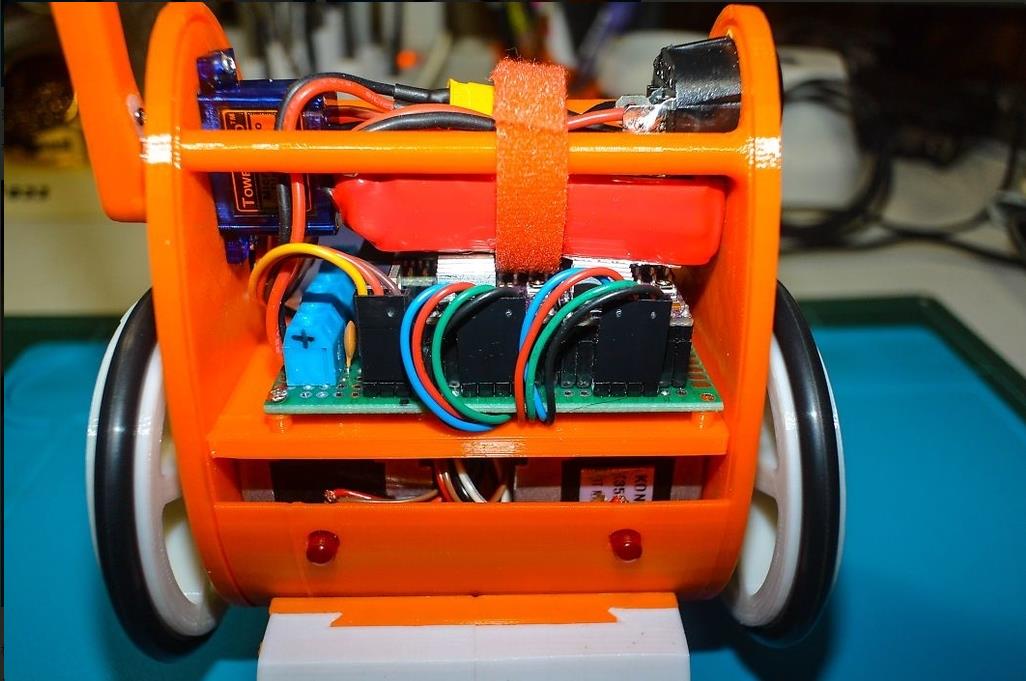

通用板使用 70mm × 50mm。

ESP32 和 DRV8825 母头的排针和步进电机和伺服的排针如图所示,短排针母头放在 ESP32 下方进行MPU6050,5V稳压器很热,所以安装了散热器,它的右侧用于电源和开关。它是一个块连接器。

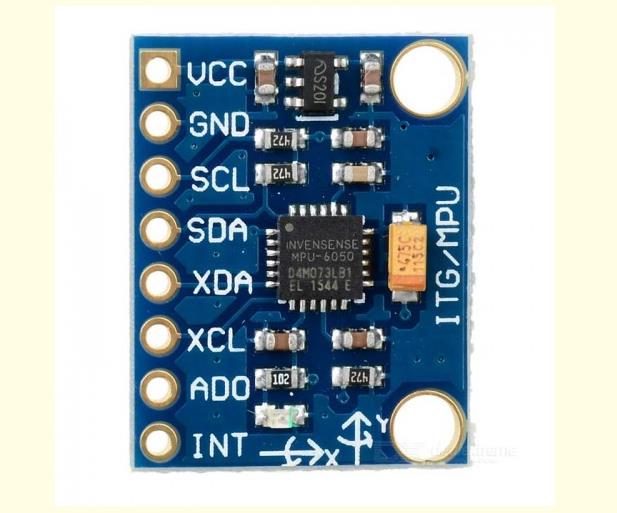

MPU6050使用云台控制器自带的,商用MPU6050上的引脚数量不同,需要注意安装方向。

图片的正面是正向方向,在这个MPU6050的情况下,在这个方向上,在商业MPU6050的情况下,它看起来像下图。

从机架的开发图可以看出,底座用2mm的自攻螺钉安装在板上的板上,步进电机用8mm×3mm的螺钉固定。

切割板板和侧框的 3 毫米丝锥,并用尼龙螺钉固定(如果没有丝锥,3 毫米丝锥也可以)。

车轮安装有O型圈,切一个3mm的丝锥并用imo螺钉固定在轴上,伺服从背面用2mm的丝锥螺钉固定为SG90,舵机从正面插入MG90S并用丝锥螺钉固定,开关推入。

如图所示,电池用魔术贴固定在车架上,顺便说一句,连接器是从左侧开始的,按照伺服、左电机和右电机的顺序(从车身背面看)。

框架盖是一块0.5mm的PVC板,切成83mm×160mm,插入框架的凹槽中,将插图印刷粘贴在印章的印刷纸上。

B-Robot 论坛上发布的文章中有 Github 的链接,所以下载 zip 文件,问题的解决方法也在论坛中讨论,请大家读到最后。

我用Arduino IDE写作,所以是给用过的人准备的,网上有很多方法使用,这里就省略了。

您将需要 ESP32 库。

另外,Arduino IDE版本是Ver1.8.7,编译时出错,所以我使用了Ver1.9.0的测试版。

首先,解压从 Github 下载的 zip 文件,并将生成文件夹中的“BRobotEvo2ESP32”文件夹移动到要与 Arduino 一起使用的文件夹(通常是文档中的 Aruduino 文件夹),尽管该文件夹中有 14 个文件。删除“BRobotEvo2ESP32.ino”,因为它只包含消息,并将“ESP32SelfbalancingBot.CPP”文件重命名为“ESP32SelfbalancingBot.ino”。

另外,论坛上写的缺陷有修复,但我不记得我修复了哪个文件,所以我把这个单元3修改过的文件放在一起,做成一个Zip文件,所以我会上传它们。

B-Robot_ESP32_ZIP_file

在写草图之前,请拆下伺服连接器和电池,以防止不必要的作。

步进电机驱动器电流值调整

写入成功完成后,调整步进电机驱动器的电流值,首先在舵机和左右步进电机连接器断开的情况下测量电流值。就这个机器人而言,它的电流约为150mA

断电后,连接一个步进电机,接通电源,步进电机运行时的电流值通过驱动模块上的音量调节到250mA左右,另一个也以同样的方式调节。

这个现值对我来说刚刚好,但可能存在个体差异,所以还是实际作调整一下比较好,调整完成后,连接好所有连接器,躺着打开电源,过一会儿车轮会微微移动,当运动停止时,慢慢抬起车身,它就会站起来。

在智能手机上进行控制

jjrobots 发布了一个适用于 Android 和 iOS 的应用程序,我使用的是 Android 智能手机,所以我从 Google Play 安装了该应用程序。

当您打开 B-Robot 时,智能手机的 WiFi 设置列表中会显示“Bbot”,选择它,输入密码“12345678”,然后连接。

启动应用程序并选择“B-ROBOT EVO2”进行控制。

伺服系统可以通过右侧的按钮进行作,PID 可以通过智能手机的设置屏幕进行调整。

*笔记

如果在机器人站立时连接智能手机,作会停止片刻,机器人会摔倒,所以在机器人倒下时将智能手机连接到WiFi,然后让机器人站起来,然后在能够用智能手机控制它后让机器人站起来。

项目代码

#include <Arduino.h>

#include <WiFi.h>

#include <WiFiClient.h>

#include <ArduinoOTA.h>

#include <Wire.h>

#include "MPU6050.h"

#include <stdio.h>

#include "esp_types.h"

#include "soc/timer_group_struct.h"

#include "driver/periph_ctrl.h"

#include "driver/timer.h"

#include "driver/ledc.h"

#include "defines.h"

#include "globals.h"

#include "Motors.h"

#include "Control.h"

#include <WiFiUdp.h>

#include "OSC.h"

#include "esp32-hal-ledc.h"

void initTimers();

void initWifiAP() {

//Serial.println("Setting up WiFi AP...");

if (WiFi.softAP("bbot", "12345678")) {

Serial.println("Wifi AP set up successfully");

}

WiFi.softAPConfig(IPAddress(192, 168, 4, 1), IPAddress(192, 168, 4, 1),

IPAddress(255, 255, 255, 0));

}

void initMPU6050() {

MPU6050_setup();

delay(500);

MPU6050_calibrate();

}

void setup() {

pinMode(PIN_ENABLE_MOTORS, OUTPUT);

digitalWrite(PIN_ENABLE_MOTORS, HIGH);

pinMode(PIN_MOTOR1_DIR, OUTPUT);

pinMode(PIN_MOTOR1_STEP, OUTPUT);

pinMode(PIN_MOTOR2_DIR, OUTPUT);

pinMode(PIN_MOTOR2_STEP, OUTPUT);

pinMode(PIN_SERVO, OUTPUT);

ledcSetup(6, 50, 16); // channel 6, 50 Hz, 16-bit width

ledcAttachPin(PIN_SERVO, 6); // GPIO 22 assigned to channel 1

delay(50);

ledcWrite(6, SERVO_AUX_NEUTRO);

Serial.begin(115200);

Wire.begin();

initWifiAP();

initMPU6050();

initTimers();

OSC_init();

digitalWrite(PIN_ENABLE_MOTORS, LOW);

for (uint8_t k = 0; k < 5; k++) {

setMotorSpeedM1(5);

setMotorSpeedM2(5);

ledcWrite(6, SERVO_AUX_NEUTRO + 250);

delay(200);

setMotorSpeedM1(-5);

setMotorSpeedM2(-5);

ledcWrite(6, SERVO_AUX_NEUTRO - 250);

delay(200);

}

ledcWrite(6, SERVO_AUX_NEUTRO);

digitalWrite(PIN_ENABLE_MOTORS, HIGH);

}

void processOSCMsg() {

if (OSCpage == 1) {

if (modifing_control_parameters) // We came from the settings screen

{

OSCfader[0] = 0.5; // default neutral values

OSCfader[1] = 0.5;

OSCtoggle[0] = 0; // Normal mode

mode = 0;

modifing_control_parameters = false;

}

if (OSCmove_mode) {

//Serial.print("M ");

//Serial.print(OSCmove_speed);

//Serial.print(" ");

//Serial.print(OSCmove_steps1);

//Serial.print(",");

//Serial.println(OSCmove_steps2);

positionControlMode = true;

OSCmove_mode = false;

target_steps1 = steps1 + OSCmove_steps1;

target_steps2 = steps2 + OSCmove_steps2;

} else {

positionControlMode = false;

throttle = (OSCfader[0] - 0.5) * max_throttle;

// We add some exponential on steering to smooth the center band

steering = OSCfader[1] - 0.5;

if (steering > 0)

steering = (steering * steering + 0.5 * steering)

* max_steering;

else

steering = (-steering * steering + 0.5 * steering)

* max_steering;

}

if ((mode == 0) && (OSCtoggle[0])) {

// Change to PRO mode

max_throttle = MAX_THROTTLE_PRO;

max_steering = MAX_STEERING_PRO;

max_target_angle = MAX_TARGET_ANGLE_PRO;

mode = 1;

}

if ((mode == 1) && (OSCtoggle[0] == 0)) {

// Change to NORMAL mode

max_throttle = MAX_THROTTLE;

max_steering = MAX_STEERING;

max_target_angle = MAX_TARGET_ANGLE;

mode = 0;

}

} else if (OSCpage == 2) { // OSC page 2

if (!modifing_control_parameters) {

for (uint8_t i = 0; i < 4; i++)

OSCfader[i] = 0.5;

OSCtoggle[0] = 0;

modifing_control_parameters = true;

OSC_MsgSend("$P2", 4);

}

// User could adjust KP, KD, KP_THROTTLE and KI_THROTTLE (fadder1,2,3,4)

// Now we need to adjust all the parameters all the times because we dont know what parameter has been moved

Kp_user = KP * 2 * OSCfader[0];

Kd_user = KD * 2 * OSCfader[1];

Kp_thr_user = KP_THROTTLE * 2 * OSCfader[2];

Ki_thr_user = KI_THROTTLE * 2 * OSCfader[3];

// Send a special telemetry message with the new parameters

char auxS[50];

sprintf(auxS, "$tP,%d,%d,%d,%d", int(Kp_user * 1000),

int(Kd_user * 1000), int(Kp_thr_user * 1000),

int(Ki_thr_user * 1000));

OSC_MsgSend(auxS, 50);

#if DEBUG>0

Serial.print("Par: ");

Serial.print(Kp_user);

Serial.print(" ");

Serial.print(Kd_user);

Serial.print(" ");

Serial.print(Kp_thr_user);

Serial.print(" ");

Serial.println(Ki_thr_user);

#endif

// Calibration mode??

if (OSCpush[2] == 1) {

Serial.print("Calibration MODE ");

angle_offset = angle_adjusted_filtered;

Serial.println(angle_offset);

}

// Kill robot => Sleep

while (OSCtoggle[0] == 1) {

//Reset external parameters

PID_errorSum = 0;

timer_old = millis();

setMotorSpeedM1(0);

setMotorSpeedM2(0);

digitalWrite(PIN_ENABLE_MOTORS, HIGH); // Disable motors

OSC_MsgRead();

}

}

}

void loop() {

OSC_MsgRead();

if (OSCnewMessage) {

OSCnewMessage = 0;

processOSCMsg();

}

timer_value = micros();

if (MPU6050_newData()) {

MPU6050_read_3axis();

loop_counter++;

slow_loop_counter++;

dt = (timer_value - timer_old) * 0.000001; // dt in seconds

timer_old = timer_value;

angle_adjusted_Old = angle_adjusted;

// Get new orientation angle from IMU (MPU6050)

float MPU_sensor_angle = MPU6050_getAngle(dt);

angle_adjusted = MPU_sensor_angle + angle_offset;

if ((MPU_sensor_angle > -15) && (MPU_sensor_angle < 15))

angle_adjusted_filtered = angle_adjusted_filtered * 0.99

+ MPU_sensor_angle * 0.01;

#if DEBUG==1

Serial.print(dt);

Serial.print(" ");

Serial.print(angle_offset);

Serial.print(" ");

Serial.print(angle_adjusted);

Serial.print(",");

Serial.println(angle_adjusted_filtered);

#endif

//Serial.print("\t");

// We calculate the estimated robot speed:

// Estimated_Speed = angular_velocity_of_stepper_motors(combined) - angular_velocity_of_robot(angle measured by IMU)

actual_robot_speed = (speed_M1 + speed_M2) / 2; // Positive: forward

int16_t angular_velocity = (angle_adjusted - angle_adjusted_Old) * 25.0; // 25 is an empirical extracted factor to adjust for real units

int16_t estimated_speed = -actual_robot_speed + angular_velocity;

estimated_speed_filtered = estimated_speed_filtered * 0.9

+ (float) estimated_speed * 0.1; // low pass filter on estimated speed

#if DEBUG==2

Serial.print(angle_adjusted);

Serial.print(" ");

Serial.println(estimated_speed_filtered);

#endif

if (positionControlMode) {

// POSITION CONTROL. INPUT: Target steps for each motor. Output: motors speed

motor1_control = positionPDControl(steps1, target_steps1,

Kp_position, Kd_position, speed_M1);

motor2_control = positionPDControl(steps2, target_steps2,

Kp_position, Kd_position, speed_M2);

// Convert from motor position control to throttle / steering commands

throttle = (motor1_control + motor2_control) / 2;

throttle = constrain(throttle, -190, 190);

steering = motor2_control - motor1_control;

steering = constrain(steering, -50, 50);

}

// ROBOT SPEED CONTROL: This is a PI controller.

// input:user throttle(robot speed), variable: estimated robot speed, output: target robot angle to get the desired speed

target_angle = speedPIControl(dt, estimated_speed_filtered, throttle,

Kp_thr, Ki_thr);

target_angle = constrain(target_angle, -max_target_angle,

max_target_angle); // limited output

#if DEBUG==3

Serial.print(angle_adjusted);

Serial.print(" ");

Serial.print(estimated_speed_filtered);

Serial.print(" ");

Serial.println(target_angle);

#endif

// Stability control (100Hz loop): This is a PD controller.

// input: robot target angle(from SPEED CONTROL), variable: robot angle, output: Motor speed

// We integrate the output (sumatory), so the output is really the motor acceleration, not motor speed.

control_output += stabilityPDControl(dt, angle_adjusted, target_angle,

Kp, Kd);

control_output = constrain(control_output, -MAX_CONTROL_OUTPUT,

MAX_CONTROL_OUTPUT); // Limit max output from control

// The steering part from the user is injected directly to the output

motor1 = control_output + steering;

motor2 = control_output - steering;

// Limit max speed (control output)

motor1 = constrain(motor1, -MAX_CONTROL_OUTPUT, MAX_CONTROL_OUTPUT);

motor2 = constrain(motor2, -MAX_CONTROL_OUTPUT, MAX_CONTROL_OUTPUT);

int angle_ready;

if (OSCpush[0]) // If we press the SERVO button we start to move

angle_ready = 82;

else

angle_ready = 74; // Default angle

if ((angle_adjusted < angle_ready) && (angle_adjusted > -angle_ready)) // Is robot ready (upright?)

{

// NORMAL MODE

digitalWrite(PIN_ENABLE_MOTORS, LOW); // Motors enable

// NOW we send the commands to the motors

setMotorSpeedM1(motor1);

setMotorSpeedM2(motor2);

} else // Robot not ready (flat), angle > angle_ready => ROBOT OFF

{

digitalWrite(PIN_ENABLE_MOTORS, HIGH); // Disable motors

setMotorSpeedM1(0);

setMotorSpeedM2(0);

PID_errorSum = 0; // Reset PID I term

Kp = KP_RAISEUP; // CONTROL GAINS FOR RAISE UP

Kd = KD_RAISEUP;

Kp_thr = KP_THROTTLE_RAISEUP;

Ki_thr = KI_THROTTLE_RAISEUP;

// RESET steps

steps1 = 0;

steps2 = 0;

positionControlMode = false;

OSCmove_mode = false;

throttle = 0;

steering = 0;

}

// Push1 Move servo arm

if (OSCpush[0]) // Move arm

{

if (angle_adjusted > -40)

ledcWrite(6, SERVO_MIN_PULSEWIDTH);

else

ledcWrite(6, SERVO_MAX_PULSEWIDTH);

} else

ledcWrite(6, SERVO_AUX_NEUTRO);

// Servo2

//ledcWrite(6, SERVO2_NEUTRO + (OSCfader[2] - 0.5) * SERVO2_RANGE);

// Normal condition?

if ((angle_adjusted < 56) && (angle_adjusted > -56)) {

Kp = Kp_user; // Default user control gains

Kd = Kd_user;

Kp_thr = Kp_thr_user;

Ki_thr = Ki_thr_user;

} else // We are in the raise up procedure => we use special control parameters

{

Kp = KP_RAISEUP; // CONTROL GAINS FOR RAISE UP

Kd = KD_RAISEUP;

Kp_thr = KP_THROTTLE_RAISEUP;

Ki_thr = KI_THROTTLE_RAISEUP;

}

} // End of new IMU data

// Medium loop 7.5Hz

if (loop_counter >= 15) {

loop_counter = 0;

// Telemetry here?

#if TELEMETRY_ANGLE==1

char auxS[25];

int ang_out = constrain(int(angle_adjusted * 10), -900, 900);

sprintf(auxS, "$tA,%+04d", ang_out);

OSC_MsgSend(auxS, 25);

#endif

#if TELEMETRY_DEBUG==1

char auxS[50];

sprintf(auxS, "$tD,%d,%d,%ld", int(angle_adjusted * 10), int(estimated_speed_filtered), steps1);

OSC_MsgSend(auxS, 50);

#endif

} // End of medium loop

else if (slow_loop_counter >= 100) // 1Hz

{

slow_loop_counter = 0;

// Read status

#if TELEMETRY_BATTERY==1

BatteryValue = (BatteryValue + BROBOT_readBattery(false)) / 2;

sendBattery_counter++;

if (sendBattery_counter >= 3) { //Every 3 seconds we send a message

sendBattery_counter = 0;

Serial.print("B");

Serial.println(BatteryValue);

char auxS[25];

sprintf(auxS, "$tB,%04d", BatteryValue);

OSC_MsgSend(auxS, 25);

}

#endif

} // End of slow loop

}【Arduino 动手做】B-Robot ESP32 版本 Unit 3 自平衡机器人

项目链接:

https://blogdaichan.hatenablog.com/entry/%3Fp%3D7129

https://blogdaichan.hatenablog.com/entry/%3Fp%3D7165

项目作者:大酱(id:blogdaichan)

项目视频:https://www.youtube.com/watch?v=42CqTkvmGMg

项目代码:https://github.com/ghmartin77/B-ROBOT_EVO2_ESP32

https://github.com/ghmartin77/B-ROBOT_EVO2_ESP32/blob/master/BRobotEvo2ESP32/ESP32SelfbalancingBot.cpp

https://drive.google.com/file/d/1mPW7OObvRVnkpS-6l-aGJaYy3k2D7bsu/view

3D打印文件:https://drive.google.com/file/d/1ec8WGoU-F8mJtrSDKjlTmDEM9zWmjJbQ/view

返回首页

返回首页

回到顶部

回到顶部

评论